What is Heat Transfer Printing

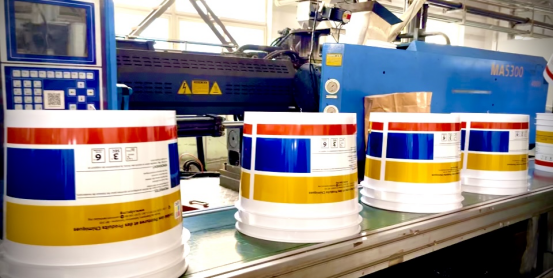

Heat transfer printing is the most widely used decoration method in Innopack® plastic Bucket manufacturing. It can transfer designed graphics, logos, bar codes, and textures onto the surface of plastic pails via using heat and pressure.

Watch this video for an overview of the heat transfer printing process!

A special printer prints the design on heat transfer paper using special inks made for printing on plastic. We apply the PET film to the plastic pails using heat and pressure.

The ink transfers from the paper to the bucket after a complete rotation. This happens because of the heat pressure works . And the result is a clear and long-lasting design.

As a modern plastic manufacturer, Mechanical automation upgrading is the key to fit global plastic industrial needs. Using a robotic arm, we create a production line that makes buckets, prints decorations, and sets metal handles all under the same roof. We combined 3 different functional machines for this process at same time to instead of slow handcraft. That allows us to Reach to produce more than 1500 pieces every 8 hours.

Simple 8 Steps heat transfer printing process on your buckets

Here is an example describing how plastic bucket decorating works. This processing of heat transfer printing breaks down into 8 steps to make an excellent.

- Select your Buckets:We are delighted to present you with a comprehensive selection of Plastic Buckets & Pails!

- Designing:Design your bucket using photo-editing software, considering size, color, text, codes, and arrangement for a perfect fit.

- PET FilmReady: Polyethylene terephthalate makes high-quality transfer papers for printing PET Film – Innopack®. It applies a heat transfer coating to a paper called “PET paper”. The paper then transforms into a tape that machines use. You can use special inks on a sublimation paper or film, with a variety of options available.

- Heat Check:check and turn on the heat press machine, which will heat for printing. Experts recommend setting the temperature between 350 and 375°F (177 to 191°C) for most heat transfer purposes.

- Pressure Check:Change the force applied based on how thick the plastic bucket is; softer plastic materials require less printing press. Typically, we utilize either medium or high pressure for the majority of tasks.

- Input three parameters: bucket open perimeter, bucket bottom perimeter, and bucket height to automatically calculate the action trajectory on the PLC control system.

- Install printing paper: Place your product on the roller and put the transfer paper face up where you want it on your product. (if it is a semi-auto heat transfer labeling machine)

- Remove the buckets:Every printing process is about 4-6 seconds. then the mechanical robotic arm will catch the bottom of the decorated bucket onto the conveyor.

Why I chose Heat Transfer Printing for Decorating Plastics.

Innopack®, the expert plastic bucket supplier, offers competitive product features and manufacturing printing processes. Keep reading to learn how we are currently using heat transfer printing on your buckets.

- The fastest printing speed can reach 4 seconds

- High Definition Images

- Cost-effective

- Eco-friendly to pail factory

- World-class customer SERVICE

- One station produces from bucket making to delivery

- Fully automatic batch production

- Customized printing

- suitable in food-grade containers

Decorating Guideline

Thermal Transfer Print is a way to apply a digital print by melting a ribbon coating onto your product. here we provide some suggestions for your order

- Please provide the correct files (e.g. AI files) for artwork. Innopack® can assist in turning your packaging concept into reality.

- Make your graphic simple, simple prints have the most impact on your potential customers

- Set up fee applies:The standard minimum order quantity (MOQ)Printing factories are typically 800 square meters, equal to about 2000 film sheets for 20L plastic buckets. Orders below this require a $100 startup fee.

- We will process the order once we receive payment and approve the artwork.

Heat Transfer Printing is one of the most cost-effective you deserve services. the result is quick, affordable, durable, waterproof, and prevents peeling and color fading. The machine heats and prints on packages and drums used in various sectors like food, chemical, and house decorating. It may help you face fewer quantity demands please read our Screen Printing for other printing options.