Plastic Bucket Printing Processes: screen printing

What is Screen Printing

Screen printing is the most common print technology in plastic container decoration. and widely used forms of decoration in the packaging industry. the most traditional printing process that first appeared in China during the Song Dynasty.

Screen printing uses silk and a mesh frame to create shapes and openings on various surfaces. The modern packaging industry does not commonly use this traditional decorating. or you can say may not be the fastest or high-tech method, but is extremely cost-efficient.

However, it is still utilized for simple text printing. Typically, screen printing allows customers to choose from only two colors. Requires custom colors in decorating buckets please call us for more information.

Today, advanced screen printing machines can handle up to six colors. In general, products printed using screen printing tend to have lower resolution and clarity. Screen printing has a

reputation for being cost-effective, providing good coverage, and offering a simple design.

The Ink mixture

Before we started printing excellent colored designs for your custom decoration on buckets. One of the most important steps is the ink preparation. We focus on making a strong and lasting ink for printing graphics, tailored to the logo, pictures, and textures.

Because plastic printing and paper ink do not mix, plastic substrates require a separate ink. To make this special ink for plastics, you mix plastic resins, solvents, polyamide materials, and colorants.

This can guarantee outstanding properties of colloidal fluid once it is thoroughly ground and dispersed. The ink we make for plastic printing is a volatile material, which has the advantages of excellent printing performance, stable adhesion toughness, and drying rapidly.

How to Screen Print A Plastic Bucket

screen printing is a fairly involved process, with many steps shown below:

Step1:mesh preparation

Imagine when you are drawing paint, first, you need a framed board. The board consists of pieces of silk stretched tightly over a wooden or metal frame, forming the screen. Don’t make the screen too loose or too tight, otherwise, it will perform unclear graphics, easily tear the picture, or peel off.

Step2: Screen making

Once we stretch the screen, It prints with a light-sensitive chemical emulsion (photographic process). When a photo is too bright, it takes more pictures on the film’s light-sensitive layers, like photography.

We attach a clear plastic sheet with the desired print onto the emulsion-coated screen using tape. We use a metal light box to control the brightness and quality of light. The light goes to the screen in our plastic container packaging.

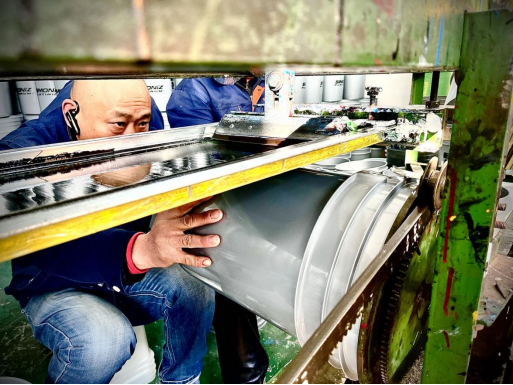

Step3:Machine Set Up

They are adjusting the semi-automatic print machine. We fit the dimensions of the container

(plastic buckets and pails) to ensure it prints correctly on the surface. Once the screen is positioned at the right angle on the device. the operator can use their foot to press the pedal, which initiates the rotation of the bucket.

Step4: Printing your dream

Screen printing is a procedure of pressing ink through the holes in the shape of the image previously burned into the screen. To have good visuals, it’s important to keep an object or device spinning at the same speed. During this repeated-printing process, every 18 seconds Innopack® packaging improves your product more much professional outlook.

Step5:Drying and Cleaning

When we complete the plastic bucket printing process. You must dry the products. We put all printed containers in a specific temperature room for fast drying.

This process allows the ink to tick on and adhere to the container for long-lasting. Then your plastic buckets are ready for stacking and delivery worldwide.

Characteristics

1.Perfect matching on plastic product

2.The printed plastic products will not fade or peel off;

3.Fully Customized and No creative restrictions

4.Steam resistant and waterproof;

5.Clean look, No label edges;

6.Extremely cost-efficient;

7.Easily recyclable;

8.Fully Customized and No creative restrictions;

9.Easy operation, & fast delivery;

10.Long-lasting and durable graphics

11.Compatible for all types of plastic bucket manufacturing

12.Detoxed and Dried before transportation

This article provides a comprehensive understanding of screen printing and how it works. Innopack® screening printing is professional and suits one and two-color designs. If you will plan a multi-color printing for large quantities of buckets or plastic containers.

I highly recommend you consider an in-molding labeling (for larger quantities) or a heat transfer printing process. Please continue to follow us and feel free to inquire with us about your optimal packaging plan.